Basic Instruction1060 Aluminum plate is widely used in products with low strength requirements. Products are commonly used in signboards, billboards, building appearance decoration, bus body, wall decoration of high-rise buildings and factories, kitchen sink, lamp holder, fan blade, electronic parts, chemical instruments, sheet metal processing parts, deep drawing or spinning concave utensils, welding parts, heat exchangers, clock surface and disk surface, nameplates, kitchenware, decorations, reflective appliances, etc.SpecificationAI(%)Si(%)Cu(%)Mg(%)Zn(%)Mn(%)Ti(%)V(%)Fe(%)99,600.250.0

Contacta ahora

High quality insulation aluminum skin,Aluminium coil manufacturer,Aluminium coil dealer.What are the advantages of insulating aluminum skin?1, beauty, as the saying goes, "Buddha by gold, people by clothes", appearance wrapped with a layer of insulation aluminum skin, then the beauty of the pipeline is greatly increased, thermal insulation aluminum plate, thermal insulation aluminum skin, aluminum skin price,1060 aluminum plate, aluminum plate price with the current popular words is immediately "high".2, the main purpose of using thermal insulation aluminum skin is to exten

Contacta ahora

Basic InstructionAluminum plate is significantly applied in products with low strength requirements.

Contacta ahora

Shandong Pingyin Chengye plate Co., Ltd. is a set of aluminum and aluminum alloy production and operation in one of the integrated enterprise, The main products are aluminum and aluminum alloy plate, aluminum coil, aluminum strip, aluminum foil, aluminum bar, aluminium pipe, aluminum wire, aluminum ingots and other products through the ISO9001: 2000 quality system certification. The company's prompt delivery, high quality and low price, service and thoughtful.

Contacta ahora

Shandong Pingyin Chengye plate Co., Ltd. is a set of aluminum and aluminum alloy production and operation in one of the integrated enterprise, The main products are aluminum and aluminum alloy plate, aluminum coil, aluminum strip, aluminum foil, aluminum bar, aluminium pipe, aluminum wire, aluminum ingots and other products through the ISO9001: 2000 quality system certification. The company's prompt delivery, high quality and low price, service and thoughtful.

Contacta ahora

Basic Instruction1060 aluminum plate is broadly applied in products with low electricity necessities.

Contacta ahora

Aluminum sheet supplier,Aluminum manufacturer,Aluminium sheet manufacturer.1060 aluminum plate belongs to industrial pure aluminum, has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but low strength, heat treatment can not be strengthened, cutting is not good; Can be gas welding, hydrogen welding and contact welding, not easy to braze; Easy to withstand a variety of pressure processing and extension, bending.1060 aluminum plate is widely used in low strength requirements of products.

Contacta ahora

Basic InstructionAluminum plate is substantially carried out in merchandise with low power requirements.

Contacta ahora

Basic Instruction1060 aluminum plate is extensively applied in merchandise with low strength requirements.

Contacta ahora

Basic InstructionAluminum plate is extensively utilized in merchandise with low power requirements.

Contacta ahora

Basic Instruction1060 aluminum plate is broadly utilized in products with low electricity requirements.

Contacta ahora

Material name: aluminum and aluminum alloy extruded bar (≤ 150mm, h112, T6, O state) standard: GB / T characteristics and scope of application: ① 5052 is an Al Mg alloy, which is widely used, especially in the construction industry. It is the most promising alloy. Good corrosion resistance, excellent weldability, good cold workability and medium strength. The main alloy element of 5052 is magnesium, which has good forming and processing performance, corrosion resistance, weldability and medium strength.

Contacta ahora

Basic Instruction1060 Aluminum plate is widely used in products with low strength requirements. Products are commonly used in signboards, billboards, building appearance decoration, bus body, wall decoration of high-rise buildings and factories, kitchen sink, lamp holder, fan blade, electronic parts, chemical instruments, sheet metal processing parts, deep drawing or spinning concave utensils, welding parts, heat exchangers, clock surface and disk surface, nameplates, kitchenware, decorations, reflective appliances, etc.SpecificationAI(%)Si(%)Cu(%)Mg(%)Zn(%)Mn(%)Ti(%)V(%)Fe(%)99,600.250.0

Contacta ahora

classificationThe grade of aluminum alloy is representative. The following is an example of 7075T651 aluminum plate grade. The first 7 represents the aluminum and aluminum alloy group - aluminum zinc magnesium alloy. Aluminum and aluminum alloy groups are divided into nine categories.

Contacta ahora

Basic InstructionThe aluminum plate of the anode is oxidized and a skinny layer of alumina is shaped at the surface. The anodized aluminum plate improves its hardness and put on resistance, appropriate warmness resistance, the melting factor of tough anodized movie is as much as 2320k, great insulation, breakdown voltage resistance is as much as 2000V, complements the corrosion resistance, and does now no longer corrode in high-electricity salt spray for lots of hours.

Contacta ahora

Aluminum plates are generally divided into the following two types:1.

Contacta ahora

Basic InstructionAluminum coil is widely used in electronics, packaging, construction, machinery and so on. What are the uses of aluminum coils? What are the classifications of aluminum coils? Aluminum coil manufacturers answer your questions and solve your doubts.

Contacta ahora

Basic InstructionAluminum coil moreover can be known as antirust aluminum coil. The manufacturing technique of 3000 collection aluminum coil in China is pretty simple. 3000 collection aluminum coil is mainly composed of manganese. The content material cloth material is among 1.0-1.5. It is a sequence with authentic antirust function. It is usually implemented in humid environments which include air conditioner, fridge and vehicle bottom. The price is better than one thousand collection.

Contacta ahora

Basic InstructionAluminum plate refers back to the square aluminum plate manufactured from natural aluminum or aluminum alloy via stress processing (shearing or sawing) to acquire square go section and uniform thickness across the world, it is normal to call aluminum materials with thickness of extra than 0.2mm, less than 500mm, width of extra than 200mm and length of less than 16m as aluminum plate or aluminum sheet, less than zero.2mm as aluminum foil and width of less than 200mm as row or strip (of direction, with the progress of massive gadget, there are more rows with a maximum width of 6

Contacta ahora

Basic InstructionAluminum plate refers to the rectangular aluminum plate made of pure aluminum or aluminum alloy through pressure processing (shearing or sawing) to obtain rectangular cross section and uniform thickness Internationally, it is customary to call aluminum materials with thickness of more than 0.2mm, less than 500mm, width of more than 200mm and length of less than 16m as aluminum plate or aluminum sheet, less than 0.2mm as aluminum foil and width of less than 200mm as row or strip (of course, with the progress of large equipment, there are more rows with a maximum width of 6

Contacta ahora

Shandong Jincheng Aluminum Co., Ltd. produces and processes various aluminum profiles such as aluminum plates, aluminum coils, aluminum strips, aluminum foils, aluminum wires, aluminum beans, aluminum particles, etc.

Contacta ahora

Aluminum plateProfessional aluminum plate supplier, providing aluminum plates of various sizes.

Contacta ahora

The main components of the aluminum wafer uncoiling and blanking production line are: loading trolley, uncoiler, leveling machine, feeder, swing unit, special closed single point mechanical press, rapid mold change device, stacking unit, waste cutting, hydraulic system, electrical control system, etc.Technical characteristics of the production line:1. CNC is fully automatic. This production line starts from uncoiling of coiled materials to the completion of blanking of the whole roll of materials.

Contacta ahora

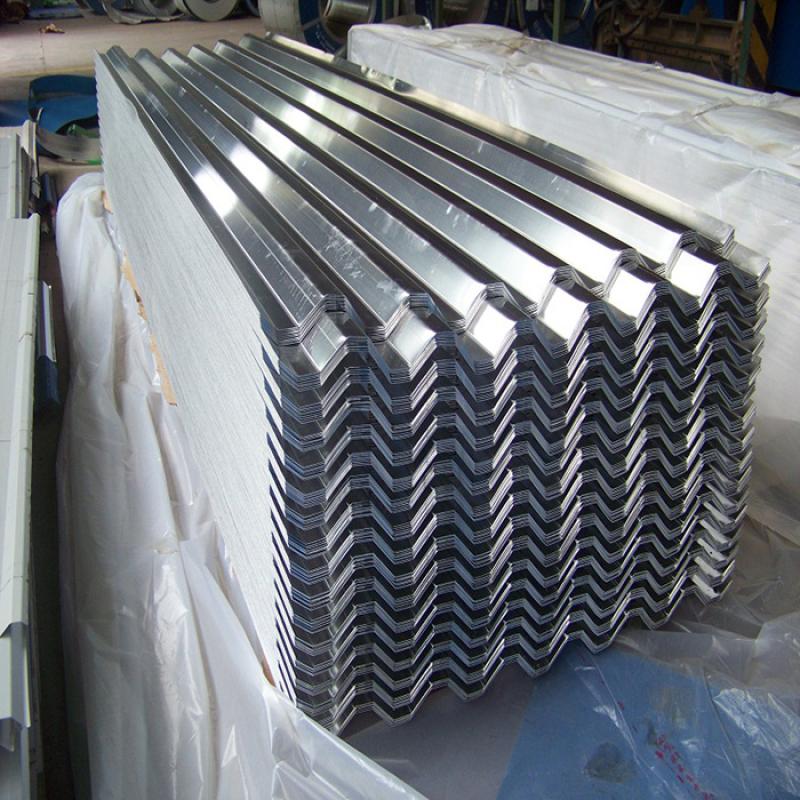

Aluminum corrugated plate, also known as corrugated aluminum plate, profiled aluminum plate, aluminum tile, etc., is a profiled plate that uses aluminum plate to roll and cold bend into various waveforms. It is suitable for the roofs, walls and interior and exterior wall decoration of industrial and civil buildings, warehouses, special buildings, large-span steel structure houses.

Contacta ahora