Anodized aluminum plate is widely used in mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, building decoration, machine shell, lamp lighting, electronic consumer goods, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries.

Contacta ahora

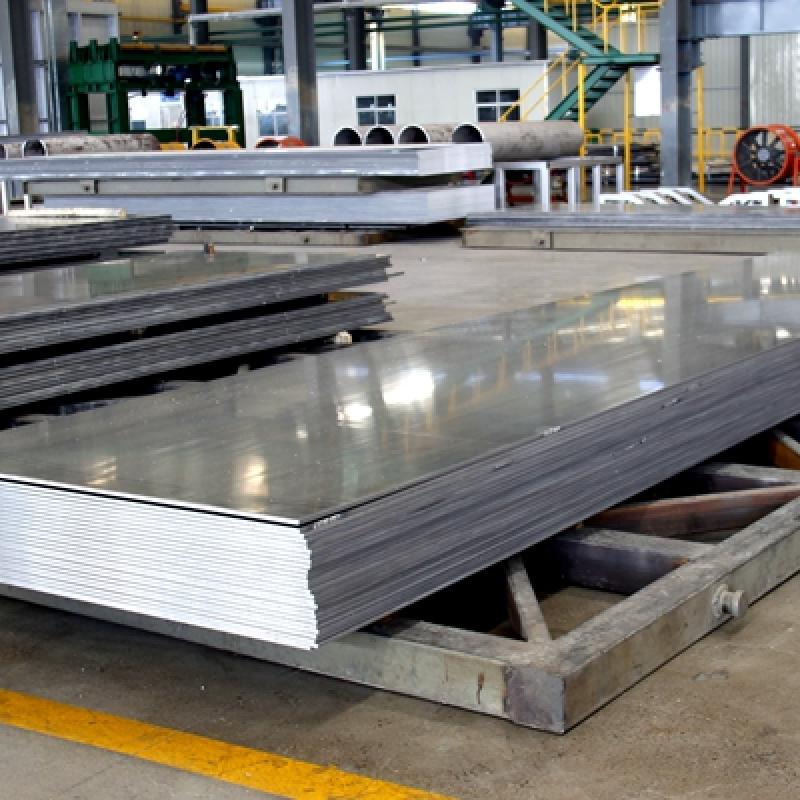

Aluminum plate,Aluminum coil,High quality aluminum oxide sheet.Aluminum oxide plate is widely used in machinery parts, aircraft and automobile parts, precision instruments and radio equipment, building decoration, machine shell, lamps and lighting, consumer electronics, crafts, household appliances, interior decoration, signs, furniture, automotive decoration and other industries.The anodic aluminum plate is oxidized to form a thin layer of alumina on the surface, the thickness of which is 5~20 microns, and the hard anodic film can reach 60~200 microns.

Contacta ahora

Application scopeAnodized aluminum plate is widely used in mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, building decoration, machine shell, lamp lighting, electronic consumer goods, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries.Advantage(1) Good processability: the positive grade aluminum oxide plate has strong decorative property and moderate hardness. It can be easily bent and formed, and can be continuously pressed at high speed.

Contacta ahora

Anodized aluminum plate is widely used in mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, architectural decoration, machine shell, lighting, electronic consumer goods, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries.advantage(1) Good processability: the positive aluminum oxide plate has strong decorative property, moderate hardness, can be easily bent and formed, and can be continuously and rapidly punched, which is convenient for direct processing into products without complicated

Contacta ahora

advantage(1) Good processability: the positive grade aluminum oxide plate has strong decorative property and moderate hardness. It can be easily bent and formed, and can be continuously pressed at high speed. It is convenient to directly process into products without complex surface treatment, which greatly reduces the product production cycle and reduces the product production cost.(2) Good weather resistance: standard thickness oxide film (3 μ m) The anodized aluminum plate can be used indoors for a long time without discoloration, corrosion, oxidation and rust.

Contacta ahora

Typical alloy 5052 aluminum plateMaterial state F, O, H12, h14,H16,H18,H19,H22,H24,H26,H28,H32,H34,H36,H38,H111,H112,H114Thickness (mm): 0.1-600Width (mm) 20-2650Length (mm): 500-16000Typical products: aluminum oxide plate, stock bin, automobile aluminum plate, mold, mask machine, electronic stamping parts, can lid, etc

Contacta ahora

5052 aluminum plate and alloy plate are widely used in such fields as ships, machinery, electronics, chemicals, building materials, decoration and so on. 5052 ultra wide aluminum plate is widely used in automobile, ship, flange material, GIS shell, yacht, underwear mold / shoe mold, air reservoir, precision machinery and many other aspects.

Contacta ahora

Global delivery,High quality aluminum plate manufacturers,Professional production of aluminum.5052 aluminum alloy sheet use: car aluminum alloy, 3C products, computer support, high-end curtain wall panel, high-end oxidation material, can tank/cover, shutter, pull rod box, aluminum furniture, door/door handle, signs, decoration and other 5052 aluminum alloy thick plate use: Silo, flange material, GIS shell, yacht, underwear mold/shoe mold, air storage cylinder, mask machine, mask machine, precision machining, etc.5052-H32 aluminum plate is used in the category of car aluminum: car engine outer

Contacta ahora

1060 Aluminum plate application1060 Aluminum plate products are commonly used for signs, billboards, exterior decoration of buildings, bus bodies, wall decoration of high-rise buildings and factories, kitchen sinks, lamp holders, fan blades, electronic parts, chemical equipment, mechanical parts, plate deep drawing or rotating concave parts, welding parts, heat exchangers, clock faces and plates, plates, kitchen utensils, ornaments, reflective equipment, etcIntroduction to 1060 series aluminum plate1060-h24 aluminum plate is a kind of 1060 Aluminum plate.

Contacta ahora

Aluminum plate is mainly used for lighting, solar reflection sheet, building appearance, ceiling, furniture, cabinet, elevator, sign, nameplate, luggage, interior and exterior decoration of automobile, refrigerator, microwave oven, audio equipment, aerospace and military aspects.

Contacta ahora

purpose1. Lighting 2. Solar reflector 3. Building appearance 4. Interior decoration: ceiling, wall, etc. 5. Furniture, cabinets 6. Elevator 7. Signs, nameplates, bags 8. Interior and exterior decoration of cars 9. Interior decoration: such as photo frames 10. Household appliances: refrigerators, microwave ovens, audio equipment, etc. 11. Aerospace and military aspects, such as China's large aircraft manufacturing, Shenzhou spacecraft series, satellites, etc. 12. Mechanical parts processing 13, mold manufacturing 14, chemical/thermal insulation pipe coating. 15. High quality ship plate

Contacta ahora

Decoration Aluminum tiles (profiled aluminum plate, corrugated aluminum plate and antique aluminum plate) have a variety of colors and shapes, beautiful appearance, bright light color, rich aluminum color and anti fading.High recovery value Aluminum plate (profiled aluminum plate, corrugated aluminum plate and antique aluminum plate) has high use value after recycling due to its corrosion resistance, and the recovery rate is more than 80%.1.

Contacta ahora

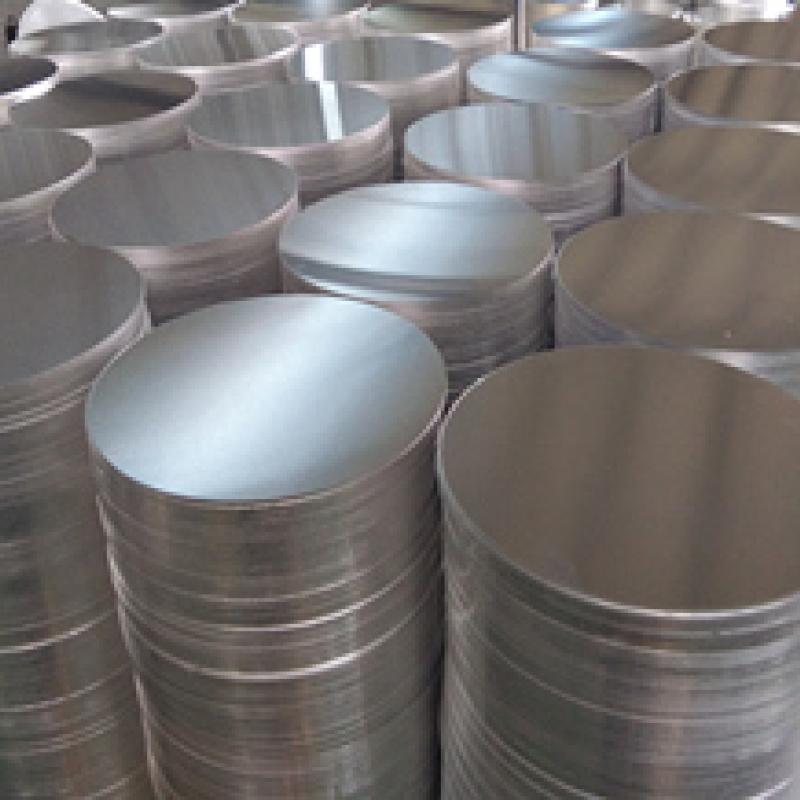

Chengye plate aluminum wafer has some advantages:1. Excellent elongation and tensile strength;2. Good processing performance, high stamping and stretch forming performance;3. Gas welding, hydrogen welding, resistance welding and brazing;4. High plasticity, conductivity and thermal conductivity;5.

Contacta ahora

advantage(1) Good processability: the positive grade aluminum oxide plate has strong decorative property and moderate hardness. It can be easily bent and formed, and can be continuously pressed at high speed. It is convenient to directly process into products without complex surface treatment, which greatly reduces the product production cycle and reduces the product production cost.(2) Good weather resistance: standard thickness oxide film (3 μ m) The anodized aluminum plate can be used indoors for a long time without discoloration, corrosion, oxidation and rust.

Contacta ahora

Anodized aluminum plate is widely used in mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, building decoration, machine shell, lamp lighting, electronic consumer goods, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries.

Contacta ahora

Basic Instruction1060 Aluminum plate is widely used in products with low strength requirements. Products are commonly used in signboards, billboards, building appearance decoration, bus body, wall decoration of high-rise buildings and factories, kitchen sink, lamp holder, fan blade, electronic parts, chemical instruments, sheet metal processing parts, deep drawing or spinning concave utensils, welding parts, heat exchangers, clock surface and disk surface, nameplates, kitchenware, decorations, reflective appliances, etc.SpecificationAI(%)Si(%)Cu(%)Mg(%)Zn(%)Mn(%)Ti(%)V(%)Fe(%)99,600.250.0

Contacta ahora

Aluminum manufacturer,Cheap aluminum sheet,Good quality aluminum plate3003 aluminum plate used for oil tank, gas or oil duct, and other various liquid containers made of deep drawing parts: small load wire used for rivet, kitchen utensils and appliances, food and chemical products processing and storage device, the transportation of liquid product tank, tank, with thin plate processing all kinds of pressure vessel and pipeline General items, heat sink, makeup, copy machine roller, ship material.

Contacta ahora

Application of aluminum plate1. Lighting2. Solar reflector3. Architectural appearance4. Interior decoration: ceiling, wall, etc5. Furniture and cabinet6. Elevator7. Signs, nameplates and bags8. Interior and exterior decoration of automobile9. Interior decoration: such as photo frame10. Household appliances: refrigerator, microwave oven, audio equipment, etc

Contacta ahora

Aluminum corrugated plate, also known as corrugated aluminum plate, profiled aluminum plate, aluminum tile, etc., is a profiled plate that uses aluminum plate to roll and cold bend into various waveforms. It is suitable for the roofs, walls and interior and exterior wall decoration of industrial and civil buildings, warehouses, special buildings, large-span steel structure houses.

Contacta ahora

Difference between aluminum oxidation and non oxidation:1. Oxidized aluminum will form a dense oxide film on the surface of the base, so the corrosion resistance will increase, and the melting boiling point will also increase. It can be used as a heat-resistant material, while non oxidized aluminum does not have these properties.2. Oxidized aluminum has a layer of oxide film, so it is corrosion-resistant and has more stable chemical properties than aluminum. In addition, aluminum can release hydrogen when it reacts with acid and alkali, and alumina has no gas.3.

Contacta ahora

The main components of the aluminum wafer uncoiling and blanking production line are: loading trolley, uncoiler, leveling machine, feeder, swing unit, special closed single point mechanical press, rapid mold change device, stacking unit, waste cutting, hydraulic system, electrical control system, etc.Technical parameters of production line:Coil width (mm): 500-1250800-14001000-1600Coil thickness (mm): 0.4-3.0, 1.0-6.0Coil weight (kg): 8000010000Blanking diameter (mm): 85-660, 85-750100-900Blanking times (spm): 40-55Nominal pressure of press (kN): 1250160020002500Alloy stateMost of them are 1-s

Contacta ahora

FeaturesThermal conductivityThe thermal conductivity of aluminum alloy is prepared 50-60% of that of copper, that is useful to the manufacture of warmth exchangers, evaporators, heating appliances, cooking utensils, similarly to vehicle cylinder heads and radiators.Non ferromagnetismAluminum profile is non ferromagnetic, that is an critical feature for electric enterprise and digital enterprise.

Contacta ahora

Thermal insulation aluminum coil has beautiful, durable and practical functionsThe thermal insulation data can be closely connected with the decoration data, so the problem that the thermal insulation data can not be closely connected with the decoration data is solved After contact, it is not easy to fall or loosen, and enhances the wind pressure resistance of the decoration surface data The decoration surface is also diversified in color, and can be processed into various plate shapes, which can better show the characteristics of construction and decoration.

Contacta ahora

The company mainly deals in: aluminum plate, patterned aluminum plate, alloy aluminum plate, thermal insulation aluminum plate, aluminum oxide plate, brushed aluminum plate, color coated aluminum plate, aluminum coil, aluminum rod, aluminum tube, aluminum strip, aluminum foil and other products. Now the company has hot rolling production line, casting production line, cold rolling production line, shear machine, annealing furnace and other equipment. The company has passed the ISO9001:2000 system certification.

Contacta ahora