1060-h24 aluminum plate is a kind of 1060 Aluminum plate. In order to reach the state of H24, the metal is strain hardened and then partially annealed, so that its strength is about between annealing (o) and full hardness (h28).1060-h14 aluminum plate is a kind of 1060 Aluminum plate. In order to reach the h14 state, the metal is strain hardened, and the strength is about between annealing (o) and full hardness (h18).1060-h12 aluminum plate is a kind of 1060 Aluminum plate.

Contacta ahora

"Aluminum wafers aluminum wafers are widely used in electronics, daily chemicals, medicine, culture and education, and auto parts. Electrical appliances, thermal insulation, machinery manufacturing, automobile, aerospace, military industry, mold, construction, printing and other industries. Such as kitchen utensils such as non stick pots, pressure pans, and hardware supplies such as lampshades, water heater shells, and stretching tanks, it is one of the largest aluminum alloy plate and strip deep processing products."

Contacta ahora

purpose1. Lighting 2. Solar reflector 3. Building appearance 4. Interior decoration: ceiling, wall, etc. 5. Furniture, cabinets 6. Elevator 7. Signs, nameplates, bags 8. Interior and exterior decoration of cars 9. Interior decoration: such as photo frames 10. Household appliances: refrigerators, microwave ovens, audio equipment, etc. 11. Aerospace and military aspects, such as China's large aircraft manufacturing, Shenzhou spacecraft series, satellites, etc. 12. Mechanical parts processing 13, mold manufacturing 14, chemical/thermal insulation pipe coating. 15. High quality ship plate

Contacta ahora

Brushed aluminum plate: the manufacturing process of repeatedly scraping aluminum plates out of lines with sandpaper. The main process flow is divided into three parts: deaster, sand mill and water washing.

Contacta ahora

advantage(1) Good processability: the positive grade aluminum oxide plate has strong decorative property and moderate hardness. It can be easily bent and formed, and can be continuously pressed at high speed. It is convenient to directly process into products without complex surface treatment, which greatly reduces the product production cycle and reduces the product production cost.(2) Good weather resistance: standard thickness oxide film (3 μ m) The anodized aluminum plate can be used indoors for a long time without discoloration, corrosion, oxidation and rust.

Contacta ahora

Decorative aluminum plate is a kind of material with high cost in construction plate. It is used more in the application field of furniture, such as refrigerator, handle and decorative strip, etc. It will be used in the decorative aluminum plate. The decorative aluminum plate has different classification according to the different plate. According to the different patterns can also be divided.

Contacta ahora

Electrolytic zinc cathode plateEnergy saving electrolytic zinc cathode plate is composed of aluminum beam, aluminum plate and conductive clamp.

Contacta ahora

1060 Aluminum plate application1060 Aluminum plate products are commonly used for signs, billboards, exterior decoration of buildings, bus bodies, wall decoration of high-rise buildings and factories, kitchen sinks, lamp holders, fan blades, electronic parts, chemical equipment, mechanical parts, plate deep drawing or rotating concave parts, welding parts, heat exchangers, clock faces and plates, plates, kitchen utensils, ornaments, reflective equipment, etcIntroduction to 1060 series aluminum plate1060-h24 aluminum plate is a kind of 1060 Aluminum plate.

Contacta ahora

3003 antirust aluminum coil plate has high aluminum content and smooth surface.

Contacta ahora

Typical alloy 5052 aluminum plateMaterial state F, O, H12, h14,H16,H18,H19,H22,H24,H26,H28,H32,H34,H36,H38,H111,H112,H114Thickness (mm): 0.1-600Width (mm) 20-2650Length (mm): 500-16000Typical products: aluminum oxide plate, stock bin, automobile aluminum plate, mold, mask machine, electronic stamping parts, can lid, etc

Contacta ahora

Orange peel pattern aluminum plate is widely used in the following fields, such as lighting, solar reflective sheet, architectural appearance, interior decoration, furniture, cabinets, elevators, signs, nameplates, automobile interior and exterior decoration, interior decoration, household appliances, aerospace and military aspects, such as China's current large aircraft manufacturing, mechanical parts processing, mold manufacturing, chemical industry, thermal insulation pipe coating and other industries, It is believed that the application of embossed aluminum plate will be more extensive

Contacta ahora

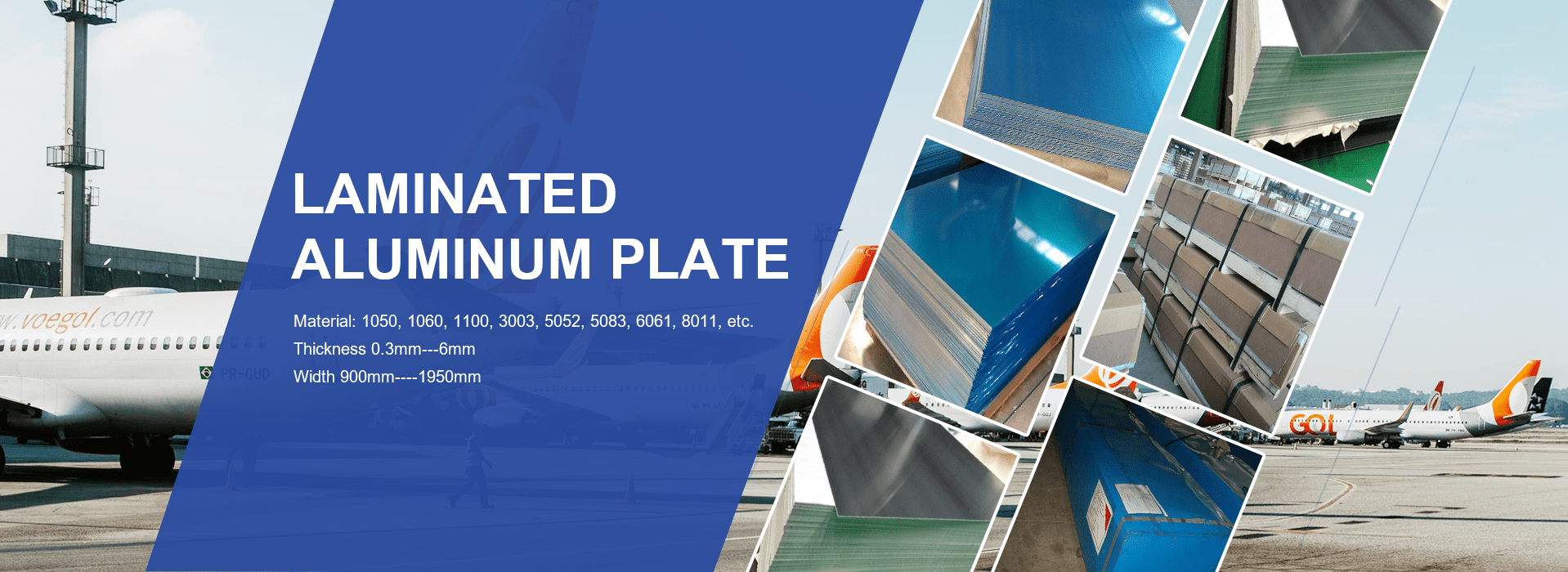

1. Pure aluminum plate: Material: 1050 / 1060 / 1070 / 1100 thickness: 0.1-500mm width: 10-2200mm2. Alloy aluminum plate: Material: 3003 / 5052 / 5754 / 5083 / 6061 / 6063 / 6082 / 7075 / 8011 thickness: 0.2-500mm width: 800-2800mm3. Curtain wall leveling aluminum plate: Material: 1060 / 1100, thickness: 0.95, 1.35, 1.5, 1.85, 2.0, 2.35, 2.5, 2.7, 2.85, 3.0mm, width: 800-1500mm2、 Aluminum coil: | aluminum foilMaterial: 1060 / 1100 / 8011 / 3003 / 3004 / 5052 thickness: 0.1-10mm width: 600-2000mm1.

Contacta ahora

Aluminum plate, as its name implies, refers to the plate material made of aluminum profile or aluminum alloy material Or it is a plate-shaped aluminum product aluminum plate produced by heating, rolling and straightening of flat aluminum embryo or aging heat of fixed banyan.1060 Aluminum plate, with an aluminum content of more than 99.6%, is also called pure aluminum plate. It is a commonly used series in the aluminum plate and belt family.

Contacta ahora

Anodized aluminum plate is widely used in mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, architectural decoration, machine shell, lighting, electronic consumer goods, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries.advantage(1) Good processability: the positive aluminum oxide plate has strong decorative property, moderate hardness, can be easily bent and formed, and can be continuously and rapidly punched, which is convenient for direct processing into products without complicated

Contacta ahora

classificationThe grade of aluminum alloy is representative. The following is an example of 7075T651 aluminum plate grade. The first 7 represents the aluminum and aluminum alloy group - aluminum zinc magnesium alloy. Aluminum and aluminum alloy groups are divided into nine categories.

Contacta ahora

1. Light weight and high strength Ruiqiao aluminum plate (profiled aluminum plate, corrugated aluminum plate and antique aluminum plate) is made of high-quality aluminum coil material, with a density of only one-third of that of steel, light weight and high strength. 2. Good weather resistance Aluminum plate (profiled aluminum plate, corrugated aluminum plate and antique aluminum plate) has good corrosion resistance, waterproof and moisture-proof, maintenance free and service life of more than 10 years. 3.

Contacta ahora

Shandong Pingyin Chengye plate Co., Ltd.

Contacta ahora

Basic Instruction1060 aluminum plate is broadly used in products with low electricity necessities.

Contacta ahora

Aluminum wafers are very common in our life. Aluminum wafers can be found in can sealing, non stick pot bottom, traffic signs, lamp covers, and so on. In addition, aluminum wafers are also frequently used in mechanical manufacturing, automobile and other industrial fields. Therefore, when purchasing aluminum wafers, the primary consideration is the use. The use determines whether to purchase hot rolled or cast rolled materials.

Contacta ahora

Aluminum plate weight calculationAluminium sheet Panzhu has more rows of 600mm wide at most). Aluminum rod, diameter: 3-500mm aluminum tube, thickness: 2-500mm, it is the theoretical calculation formula of aluminum tube, aluminum plate and aluminum rod.

Contacta ahora

Aluminum plate weight calculationAluminium sheet Panzhu has more rows of 600mm wide at most). Aluminum rod, diameter: 3-500mm aluminum tube, thickness: 2-500mm, it is the theoretical calculation formula of aluminum tube, aluminum plate and aluminum rod.

Contacta ahora

Application scopeAnodized aluminum plate is widely used in mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, building decoration, machine shell, lamp lighting, electronic consumer goods, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries.Advantage(1) Good processability: the positive grade aluminum oxide plate has strong decorative property and moderate hardness. It can be easily bent and formed, and can be continuously pressed at high speed.

Contacta ahora

Decoration Aluminum tiles (profiled aluminum plate, corrugated aluminum plate and antique aluminum plate) have a variety of colors and shapes, beautiful appearance, bright light color, rich aluminum color and anti fading.High recovery value Aluminum plate (profiled aluminum plate, corrugated aluminum plate and antique aluminum plate) has high use value after recycling due to its corrosion resistance, and the recovery rate is more than 80%.1.

Contacta ahora

Basic InstructionAluminum coil also can be known as antirust aluminum coil. The manufacturing method of 3000 collection aluminum coil in China is pretty simple. 3000 collection aluminum coil is especially composed of manganese. The content material is among 1.0-1.5. It is a chain with exact antirust function. It is usually utilized in humid environments consisting of air conditioner, fridge and vehicle bottom. The rate is better than one thousand collection.

Contacta ahora